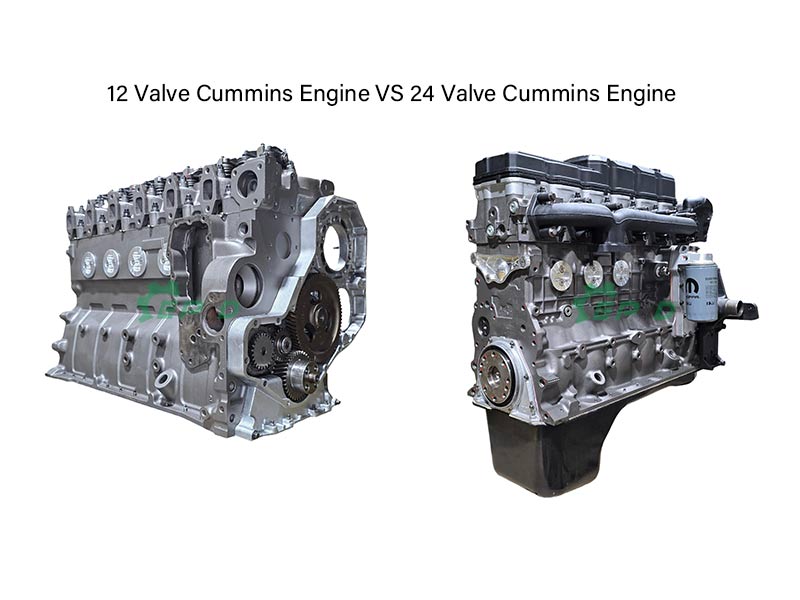

The legendary Cummins B-Series turbo-diesel engine, a cornerstone of heavy-duty performance and durability, exists primarily in two distinct mechanical generations defined by their cylinder head design: the venerable 12-valve Cummins and the more modern 24-valve Cummins. Understanding the differences between their respective Cummins engine parts, Cummins diesel components, and Cummins replacement parts is crucial for owners, mechanics, and enthusiasts seeking optimal performance, reliability, and informed maintenance decisions. Choosing the right Cummins diesel parts, whether OEM or high-quality aftermarket, hinges on recognizing these fundamental distinctions.

– Core Distinction: As the name implies, the 12-valve Cummins engine utilizes two valves per cylinder (one intake, one exhaust), totaling twelve valves for the inline-six engine. Its reign spanned the first generation of the popular 5.9L iteration.

– Fuel System Heart: The defining characteristic of 12-valve Cummins parts is the mechanical Bosch VE rotary injection pump (early models) and the legendary Bosch P7100 inline injection pump (later models, often called the “P-pump”). These pumps are purely mechanical, driven directly by the engine’s gear train. This translates to:

— Simplicity & Robustness: Fewer electronic components mean potentially greater inherent reliability in harsh conditions and easier troubleshooting for mechanically inclined individuals. Finding Cummins mechanical injection parts like pumps, injectors (Cummins fuel injectors), and lines is generally straightforward.

— Predictable Power Delivery: Power builds linearly and predictably with RPM, favored by many for towing and its raw, mechanical feel. 12-valve performance parts often focus on enhancing this mechanical system (bigger injectors, modified P-pumps).

— Tuner-Friendly: The lack of complex electronic controls makes mechanical 12-valve engines highly receptive to performance modifications using specialized Cummins diesel performance parts.

– Other Key Components: 12-valve Cummins replacement parts include specific cylinder heads with fewer ports, corresponding intake and exhaust manifolds, different rocker arms and pushrods, and engine control modules (ECMs) that handle basic functions like timing advance on later models but lack full fuel system control.

– Core Distinction: The 24-valve Cummins engine doubled the valve count to four valves per cylinder (two intake, two exhaust). This significant redesign aimed to improve breathing efficiency, fuel economy, emissions control, and power potential.

– Fuel System Revolution: The most profound shift lies in the electronically controlled Bosch VP44 rotary injection pump. While still mechanically driven, the VP44 relies entirely on electronic signals from the ECM to precisely control injection timing and fuel quantity. This necessitates:

— Advanced Electronics: A sophisticated ECM and numerous sensors are critical Cummins diesel components for the 24-valve engine. Diagnosis often requires specialized electronic scan tools.

— Enhanced Efficiency & Emissions: Electronic control allows for more precise fuel metering, optimizing combustion for better fuel economy and lower emissions compared to the purely mechanical 12-valve.

— Potential Vulnerability: The VP44 pump itself is electrically actuated and relies on clean, adequate fuel flow for lubrication and cooling. Fuel contamination or lift pump failure are common failure points for 24-valve Cummins parts, making quality Cummins fuel system parts (especially lift pumps and filters) paramount.

– Performance & Breathing: The four-valve-per-cylinder design significantly improves airflow. Combined with electronic control, this allows for smoother operation, potentially higher peak horsepower (especially in stock form vs. early 12-valve), and a broader torque curve. However, modifying 24-valve Cummins performance parts often requires addressing electronic tuning limitations.

– Other Key Components: 24-valve Cummins parts feature a different cylinder head with more ports, corresponding intake/exhaust manifolds, revised rocker assemblies, and a complex wiring harness integrating numerous sensors critical for the VP44 pump’s operation.

Maintaining peak performance and longevity for either generation demands genuine Cummins parts or high-quality aftermarket Cummins replacement parts. This is where globally recognized manufacturers and suppliers play a vital role. EPID parts, as a leading diesel engine parts manufacturer and a premier global diesel engine parts supplier based in China, exemplifies this critical segment of the industry. Companies like EPID ensure a consistent, reliable supply chain for essential Cummins engine components, Cummins diesel spare parts, and Cummins aftermarket parts worldwide. Their expertise in manufacturing and distribution helps keep these iconic engines running strong, regardless of whether they rely on mechanical ingenuity or electronic precision. Rigorous quality control in the production of Cummins diesel engine parts – from gaskets and seals to pistons, bearings, and intricate fuel system components – is essential for meeting the demanding standards these engines require.

The choice between a 12-valve and 24-valve Cummins often comes down to preference for mechanical simplicity and raw tunability versus modern efficiency, smoother operation, and evolving emissions compliance. Understanding the distinct Cummins engine parts required for each generation – from the fundamental valve configuration and cylinder head differences to the radically opposed fuel injection systems – is critical for proper maintenance, repair, and performance enhancement.

Whether seeking robust 12 valve Cummins parts or sophisticated 24 valve Cummins parts, sourcing components engineered to exacting standards is non-negotiable. EPID Parts stands at the forefront of this global supply chain, providing essential Cummins replacement parts and high-performance Cummins engine parts that power industries and enthusiasts worldwide, ensuring these diesel legends continue to deliver unmatched durability and power. Choosing premium components, like those supplied by leading manufacturers, guarantees these iconic engines perform reliably for years to come.