Within the vast landscape of diesel engines powering global industry, transportation, and power generation, Baudouin and Weichai stand as prominent manufacturers, each with its own legacy and specialization.

While both produce robust and reliable engines, the design priorities, typical applications, and consequently, the characteristics of their genuine spare parts, exhibit significant differences.

Understanding these distinctions is crucial for operators, fleet managers, and maintenance professionals to ensure optimal performance, longevity, and cost-effectiveness.

– Heritage: French engineering heritage with a century-long focus on marine propulsion and auxiliary power, along with stationary power generation (especially for critical backup and prime power).

– Priority: Exceptional reliability, robustness in harsh environments (saltwater, humidity, vibration), longevity, precise power delivery consistency, and adherence to stringent marine classification society rules (like BV, DNV, ABS, LR, etc.). Emissions compliance (IMO Tier II/III) is critical for marine applications.

– Typical Applications: Workboats (tugs, trawlers, supply vessels), passenger ferries, yachts, naval vessels, offshore support vessels, standby and prime power gensets for hospitals, data centers, and industrial facilities.

– Heritage: China’s largest and globally significant manufacturer with a vast portfolio covering trucks, buses, construction equipment, agricultural machinery, industrial, and power generation engines. Highly vertically integrated.

– Priority: Delivering robust power and torque for demanding land-based applications across diverse markets, achieving a strong cost-performance ratio, fuel efficiency, and compliance with road and non-road emissions standards (China Non-Road Stage IV, Euro V/VI equivalents).

– Typical Applications: Heavy-duty trucks, buses, excavators, wheel loaders, cranes, tractors, combine harvesters, forklifts, and industrial/mobile power generation sets.

The fundamental differences in application focus translate directly into the design philosophy and material choices for critical engine components:

– Baudouin Spare Parts: Face the relentless assault of saltwater spray, high humidity, and significant temperature fluctuations. Genuine parts prioritize:

— Superior Corrosion Protection: Extensive use of marine-grade alloys (e.g., bronze, specific stainless steels), advanced coatings (zinc-nickel, cadmium replacements, specialized paints), and sealing technologies designed to withstand saltwater intrusion long-term.

— Enhanced Sealing: Gaskets, seals (crankshaft, camshaft, valve stems), and hose materials are specifically formulated for resistance to saltwater degradation, fuel/oil immersion, and extreme heat cycling common in engine rooms. Resistance to vibration fatigue is paramount.

— Electrical Component Protection: Sensors, wiring harnesses, and connectors feature higher levels of waterproofing and corrosion resistance.

– Weichai Parts: While durable, the primary environmental challenges are dust, dirt, high ambient temperatures, and heavy mechanical loads associated with land-based equipment. Corrosion resistance is important but generally faces less severe saltwater exposure than marine engines.

– Baudouin Parts: Designed for extended service intervals and maximum lifespan in critical applications where failure is not an option (e.g., offshore, emergency power).

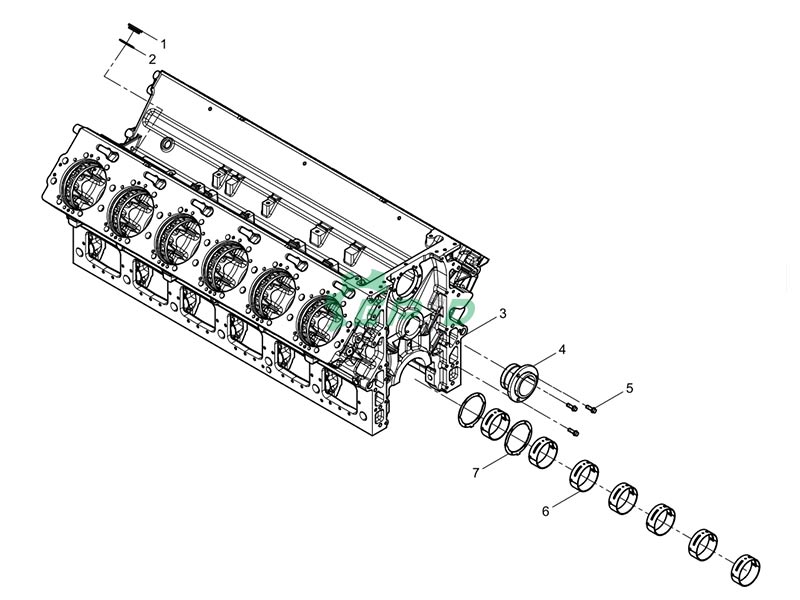

— Core Components: Crankshafts, connecting rods, and bearings often utilize high-grade forged steels and specialized bearing alloys optimized for continuous high-load operation and shock loads common in marine propulsion.

— Cylinder Components: Liners, pistons, and rings emphasize wear resistance over vast operating hours and compatibility with marine-specific lubricants and potential fuel variations.

— Precision & Tolerances: Manufacturing adheres to strict tolerances suitable for the high fuel injection pressures and precise timing required for emissions compliance and optimal efficiency under varying loads.

– Weichai Parts: Built for high reliability under demanding cyclical loads (construction, trucking) at a competitive price point. Utilize robust materials and manufacturing but may prioritize cost optimization more heavily than ultra-premium marine-focused parts. Performance targets align with the typical duty cycles of trucks and machinery.

– Baudouin Parts: Must flawlessly handle diverse marine fuels (including potentially lower quality MGO/HFO blends in auxiliary engines) and stringent IMO emissions regulations. Fuel injectors, pumps, and filters are engineered for extreme precision, durability against fuel contaminants, and compatibility with marine exhaust aftertreatment systems (SCR for NOx reduction).

– Weichai Parts: Primarily designed for cleaner on-road and off-road diesel fuels. Fuel system components (often Bosch-based Common Rail) prioritize performance and efficiency within land-based emissions frameworks (China Non-Road, Euro equivalents). Aftertreatment components (DPF, SCR) are tailored to these specific regulations.

– Baudouin Parts: Cooling systems face unique challenges: seawater coolant circuits (raw water pumps, heat exchangers) require excellent corrosion resistance (bronze, cupronickel, titanium). Freshwater circuits need reliable pumps and thermostats capable of managing heat loads in confined engine spaces.

– Weichai Parts: Primarily use closed-loop coolant systems with conventional coolant pumps and radiators/oil coolers designed for land-based airflow and cooling efficiency. Materials prioritize cost-effectiveness for standard coolants.

Using non-genuine or incorrect specification parts for either brand carries significant risks:

– For Baudouin Engines: Substandard corrosion protection leads to rapid component failure (especially in seawater circuits). Incorrect materials or tolerances cause poor reliability, increased emissions, fuel inefficiency, and potential safety hazards in critical marine or power gen applications. Voiding classification society approvals is a major risk.

– For Weichai Engines: Inferior parts can lead to premature wear, reduced power/fuel economy, increased emissions (and potential non-compliance fines), and higher long-term maintenance costs due to accelerated failure and collateral damage.

When it comes to maintaining the unparalleled reliability and longevity of your Baudouin marine propulsion or power generation engine, only parts engineered to withstand the unique marine environment will suffice. Compromise is not an option for vessels operating offshore or critical facilities relying on backup power.

EPID Parts specializes in supplying the highest quality genuine Baudouin parts and premium OEM-equivalent components specifically designed and validated for Baudouin engines. We understand the rigorous demands of the marine and stationary power sectors.

Our comprehensive Baudouin parts inventory includes:

– Critical Marine-Hardened Components: Fuel injectors & pumps, turbochargers & rebuild kits, water pumps (raw & coolant), heat exchangers, gasket & seal kits (marine-grade materials), sensors, bearings, valves, filters (fuel, oil, air – marine spec).

– Electronics & Electrical: Starters, alternators, wiring harnesses, sensors built for humidity and salt.

– Core Engine Parts: Cylinder kits (liners, pistons, rings), connecting rods, main & rod bearings, valve train components.

– Emissions System Parts: SCR components, exhaust manifolds, piping.

– Maintenance Kits: Comprehensive service kits tailored to your Baudouin model and application.

– Marine Application Expertise: We understand Baudouin’s marine DNA and the criticality of parts meeting that standard.

– Premium Quality Assurance: We source directly from Baudouin and select OEM partners adhering strictly to marine-grade specifications and tolerances. No compromises on corrosion resistance or longevity.

– Extensive Baudouin Coverage: Parts for propulsion (M26.3, M33.4, K, F, etc.) and genset engines across various generations.

– Global Support: Reliable logistics to get you the parts you need, wherever your vessel or facility operates.

– Technical Guidance: Access to knowledgeable support for part selection and application questions.

– Cost-Effective Reliability: Invest in quality upfront to avoid costly breakdowns, downtime, and safety risks at sea or during critical outages.

Secure Your Baudouin Engine’s Performance & Protect Your Investment!

Don’t risk your operations, safety, or compliance with inferior parts. EPID Parts delivers the genuine Baudouin quality and marine-specification components your engines demand for dependable performance in the world’s toughest environments.

Browse our dedicated Baudouin parts catalog online today! Need assistance identifying the exact part for your engine model or have questions about marine-specific requirements?

Leave a message below or contact our Baudouin marine parts specialists directly! We’re ready to provide expert advice, quotes, and ensure you receive the right high-performance part for your critical application. Partner with EPID for unmatched Baudouin engine support.